Research

Areas

Atom on nanoscale

Atom

nanofabrication

Reseach

topics

Atom

nanolithography

Atom

lenses

Publications

Nanophotonics

& Nanoplasmonics

Experimental

facilities

Publications

Publications

Press

about us

Patents

Team

Contacts

|

Atom nanofabrication

There

are several

approaches to fabrication of nanostructures with sizes

of several tens of nanometers; each of them has a number of advantages

and

drawbacks. In particular, the difficulties in further development of

approved

methods are well known: (i) conventional photolithography has a

diffraction

limit, (ii) lithography based on charged particle beams meets problems

related

to commercial production of structures and a significant role of

Coulomb

repulsion, (iii) scanning probes have a low output, and (iv) self

assembling

fabrication is not an universal process. An alternative approach for

nanotechnology is atom optics, i.e., optics of material particles

(electron and

ion optics). It deals with problems of formation and control of

ensembles and

beams of neutral atoms. The term “atom optics” is

similar to the terms “light

optics” or “photon optics”. An important

direction of atom optics is the

development of basic elements, similar to the elements of conventional

light

optics. Among many applications of atom optics elements, atom

lithography is

potentially important for micro and nanofabrication of material

structures. There

are several

approaches to fabrication of nanostructures with sizes

of several tens of nanometers; each of them has a number of advantages

and

drawbacks. In particular, the difficulties in further development of

approved

methods are well known: (i) conventional photolithography has a

diffraction

limit, (ii) lithography based on charged particle beams meets problems

related

to commercial production of structures and a significant role of

Coulomb

repulsion, (iii) scanning probes have a low output, and (iv) self

assembling

fabrication is not an universal process. An alternative approach for

nanotechnology is atom optics, i.e., optics of material particles

(electron and

ion optics). It deals with problems of formation and control of

ensembles and

beams of neutral atoms. The term “atom optics” is

similar to the terms “light

optics” or “photon optics”. An important

direction of atom optics is the

development of basic elements, similar to the elements of conventional

light

optics. Among many applications of atom optics elements, atom

lithography is

potentially important for micro and nanofabrication of material

structures.

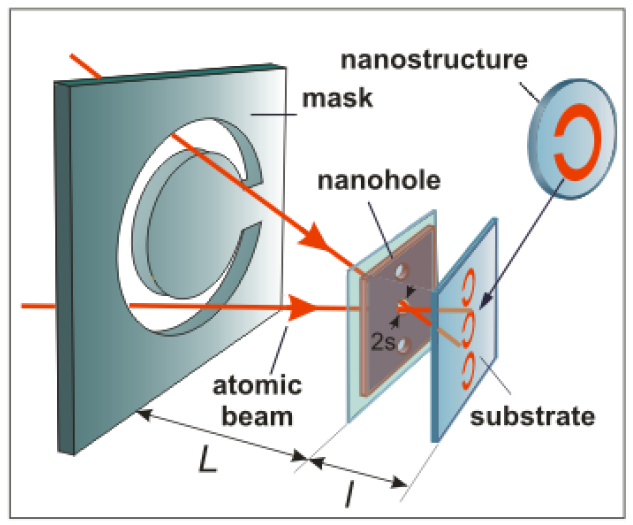

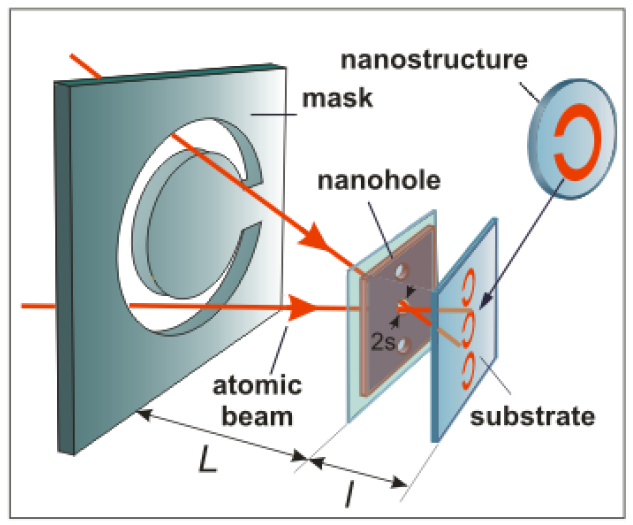

Despite a large number of

proposed methods for focusing atomic beams, this problem remains

experimentally

difficult. The main difficulty is the fabrication of the

atom–field interaction

potential with properties similar to those of the

“ideal” lens for atoms. We

experimentally implemented for the first time another approach to the

problem

of focusing and constructing images in atomic optics, which is based on

the

concept of a pinhole camera; the latter is used both in light optics

and in

modern experimental physics when it is difficult to form a focusing

potential. In an atomic “pinhole

camera”, an atomic beam is transmitted through an array of

holes in a

mask, thus forming, by analogy

with optics, a “luminous object” of specified

geometry. The atoms transmitted

through the holes in the mask, propagating in vacuum over straight-line

trajectories,

arrive at a thin film located at a distance L from

the mask. Each hole

of the film serves as a pinhole camera for atoms, forming an image of

the

“object” on the surface of a substrate, which is

located at a small distances l

behind the film. In

this geometry, a set of

object images, decreased

approximately by a factor of m

= L/l ,

is formed on the

substrate. The atomic “pinhole camera” is an analog

of the Feynman’s scalable

manufacturing system that could manufacture a smaller scale replica of

itself.

|

|

www.isan.troitsk.ru

Institute for spectroscopy RAS,

Fizicheskaya Str., 5, Troitsk, Moscow, 142190 Russia

phone: +7 495 851-02-33

e-mail: atom.nano.optics@gmail.com

|

There

are several

approaches to fabrication of nanostructures with sizes

of several tens of nanometers; each of them has a number of advantages

and

drawbacks. In particular, the difficulties in further development of

approved

methods are well known: (i) conventional photolithography has a

diffraction

limit, (ii) lithography based on charged particle beams meets problems

related

to commercial production of structures and a significant role of

Coulomb

repulsion, (iii) scanning probes have a low output, and (iv) self

assembling

fabrication is not an universal process. An alternative approach for

nanotechnology is atom optics, i.e., optics of material particles

(electron and

ion optics). It deals with problems of formation and control of

ensembles and

beams of neutral atoms. The term “atom optics” is

similar to the terms “light

optics” or “photon optics”. An important

direction of atom optics is the

development of basic elements, similar to the elements of conventional

light

optics. Among many applications of atom optics elements, atom

lithography is

potentially important for micro and nanofabrication of material

structures.

There

are several

approaches to fabrication of nanostructures with sizes

of several tens of nanometers; each of them has a number of advantages

and

drawbacks. In particular, the difficulties in further development of

approved

methods are well known: (i) conventional photolithography has a

diffraction

limit, (ii) lithography based on charged particle beams meets problems

related

to commercial production of structures and a significant role of

Coulomb

repulsion, (iii) scanning probes have a low output, and (iv) self

assembling

fabrication is not an universal process. An alternative approach for

nanotechnology is atom optics, i.e., optics of material particles

(electron and

ion optics). It deals with problems of formation and control of

ensembles and

beams of neutral atoms. The term “atom optics” is

similar to the terms “light

optics” or “photon optics”. An important

direction of atom optics is the

development of basic elements, similar to the elements of conventional

light

optics. Among many applications of atom optics elements, atom

lithography is

potentially important for micro and nanofabrication of material

structures.